Getting Started with That Old Flathead

Alright, so I finally got my hands on this beat-up Ford Flathead V8. Been sitting in some dude’s barn forever, lookin’ like it fought a war and lost bad. Dirt, grime, you name it. Step one is always the dirtiest: cleaning this mess. I grabbed my trusty degreaser cans – went through like four of ’em – and just went to town. Hose water everywhere, scrub brushes gettin’ ruined. Took me half a day just to see what was metal and what was mud cake.

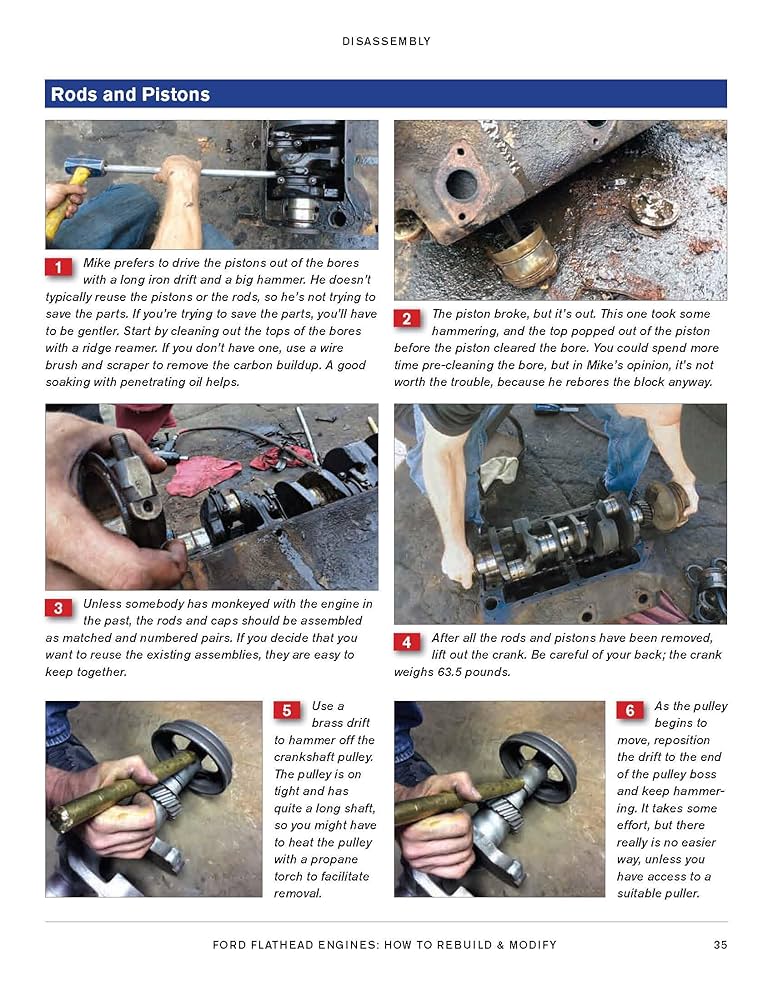

Taking the Damn Thing Apart

Next up? Tear down time. You gotta be patient, man, especially with old bolts that think they’re welded on forever. Started simple: yanked off the intake and exhaust manifolds. Then the cylinder heads. Underneath? Yeah, the pistons were kinda stuck, no surprise there. Had to tap ’em gently with a rubber mallet, coaxing ’em loose. Didn’t wanna break nothin’. Then the crankshaft bearings, oil pump… all came off one piece at a time. Threw everything into labeled buckets – labeled is key, trust me, unless you wanna play “guess this part” later.

Figuring Out What’s Trash and What’s Treasure

This part sucks. Sent everything off to the machine shop. Told ’em: “Hey, make it good.” Mostly just hoping they didn’t call back sayin’ it was toast. Got lucky though! The block needed boring out – pistons were toast – but the crank could be saved with some grinding. Valves? Yeah, they needed serious work. Seats redone, all that jazz. Machine shop bill hurt the wallet, no lie.

While they did the magic, I tackled the smaller bits:

- Scrubbed the heck outta every bolt, washer, bracket.

- Chased all the threads with a tap and die set – felt like an eternity.

- Painted the block myself in the garage. Ford dark green. Looked pretty sharp.

The Long Road to Putting It All Back

Getting the crankshaft back in is always nerve-wracking. Slathered everything in assembly lube and set it down real careful into the fresh bearings. Torque wrench clickin’ away. Then came the pistons – new rings, new pistons. Felt like playin’ Operation trying to get those rings compressed and the pistons in the holes without snapping a ring. Held my breath a lot.

Timing gears were next. Alignment marks gotta be spot on. Double-checked, triple-checked. Then the camshaft, lifters… slowly building it up from the inside out.

Finally slapped the cylinder heads back on. Head bolt torque sequence? Yeah, followed it religiously, criss-cross pattern, couple passes. Didn’t wanna warp nothin’. Water pumps, intake manifold… it was startin’ to look like an engine again.

That First Fire-Up Moment

Hooked up the fuel line, temporary tank. Fresh oil and coolant in. Battery connected. Ignition on. Said a little prayer and stabbed the starter. First time? Just cranked. Second time? A cough! Third time? Man, that glorious brap-brap-brap as it caught and settled into a lumpy idle! Smoke cleared out quick – just burning off assembly lube. Felt like a million bucks, honestly. No leaks! Well, minor drip from a drain plug, but hey, tightened it up, all good.

Now What?

Gotta break it in proper, right? Ran it at different RPMs for about 20 minutes, let it cool down. Checked all the bolts again. Feels solid. Now it’s time to stuff this old lump back into the car it came out of. That… that’s a whole ‘nother adventure. But rebuildin’ this Flathead? Total pain, totally dusty, greasy work. But hearin’ it run smooth? Worth every busted knuckle and can of degreaser. Would I do it again? Probably. I’m kinda crazy like that.